AREA OF INTEREST:Applied Science | Technology | Trades

Students who want to pursue majors within this interest area are often hands-on and require independence while working. They like creating practical and useful solutions, objects, or processes that help others to function in both work and home and taking existing knowledge and translating it into practical applications, through technology, inventions, or systems. They are problem solvers who enjoy putting together pieces in a way that is new and inventive. Sound like you? Explore the programs of study that Harford Community College offers in this interest area.

Profile

• Hands-on, mechanical, interested in how things work

• Use and adapt technologies to solve problems

• Enjoy building and creating

• May prefer to go straight into workforce

• Always looking to learn something new

• Often enjoy being active, outdoors

• Concrete problem solvers

• Work with things they can touch, see, use or improve

Work Options

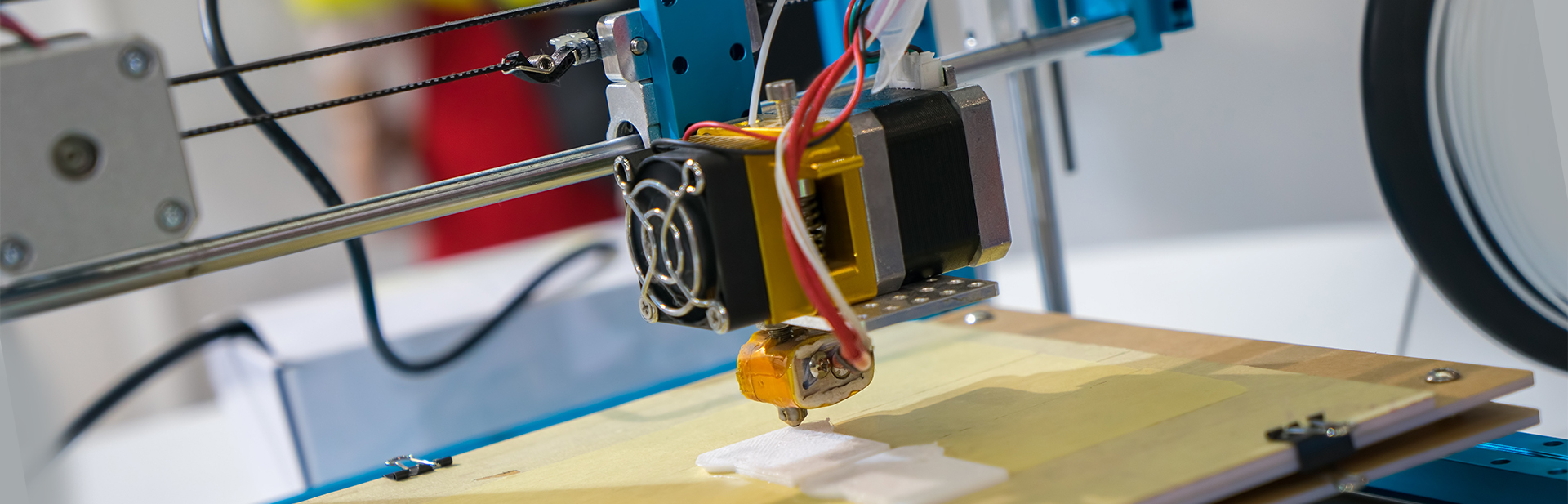

A wide variety of job opportunities as technicians and technologists exist in manufacturing, electronics, production and processing, operations, and research and development. Those entering the job market with a two-year degree may work with engineers to fabricate models or draw plans. They are the ones bringing the plans to life. Students may also pursue apprenticeship programs in trade fields such as welding, electrical, and plumbing.

Transfer Options

Although many students in this area choose to directly enter the workforce, others use these programs as stepping stones to broader fields or as an add-on to a four-year degree. Common transfer destinations lead them to advanced degrees in fields such as Biotech, Engineering, and Defense.

Get Involved

On campus opportunities in this program area include internships at local businesses and Aberdeen Proving Ground, Additive Manufacturing and Engineering opportunities with Volunteers for Medical Engineering (VME), clubs such as 3D Printing Club, Engineering Club, and Biological Outreach Initiative. Most recently, students in Additive Manufacturing have been fabricating PPE and donating them to local organizations.